Which opening system should I choose for my high-speed door?

Today, one of the most important decisions that needs to be made at any facility revolves around which door option is the best for the company‘s needs. Among all the options available, one of the most popular in recent years has been the high-speed door.

High-speed doors are the perfect way to improve efficiency and productivity at industrial premises and warehouses and they can be installed at both indoor and external access points. They are key in work areas that experience a high volume of traffic and in zones where temperature losses must be avoided between different spaces, for which reason not only do they optimise the entry and exit of goods, but they also generate significant energy savings.

As such, once you’ve selected the high-speed door for you, one of the most frequently asked questions among our customers is, “Which opening option is the best one for me?”

What do these opening systems need to provide?

- Fluid, quick access of people and goods.

- Safety to ensure doors are not blocked or easily damaged.

- Durability and reliability: the door must be reliable and robust, but so must the opening system.

- And they need to be hygienic, minimising possible contagion due to the transmission of germs or viruses.

At present, there is a wide selection of opening systems available. These range from traditional choices that have always been available on the market to newer, more digitalised options. When choosing an opening system, the customer must consider:

- What will this door be used for?

- Who or what will be using the door? Only vehicles? Only people? Or both?

- Will it need to withstand intense vehicle traffic or high volumes of people throughout the day, or will it only be used occasionally?

- Will it be situated in an area that must observe very strict hygiene conditions and/or is subject to cleaning with chemical products?

- Will it be in contact with food?

It’s not always an easy choice. Sometimes a cheaper solution is selected but this can be harmful to the facility in the medium term and end up costing the customer more. As such, in an attempt to assist you, we’re going to analyse the safety systems available and provide you with some key information to help you choose the most appropriate option for any given situation.

BUTTON PANEL WITH EMERGENCY STOP

A button panel with an emergency stop button is a manual, fail-safe control switch that quickly stops the door, offering both people and machinery safety if there is a risk of injury during the work flow.

The button panel with the emergency stop button must be visible to all users who may require it.

This button panel can also block the door if it is to be kept open for a certain amount of time in order to take in or remove goods from a specific area.

All our automatic doors are equipped with an IP67 opening button panel that features an emergency stop button (included in the price). It allows the door to be opened from the opposite side to where the control panel is installed.

PULL CORDS

Another option available to customers is a pull cord, which allows the door to open when the cord (hanging a few metres away from the door) is pulled.

This opening system is one of the most frequently used, given that it’s simple and one of the cheapest options available. In our case, we only use PVC cords for food-use, which can safely be used in the agri-food industry.

But have you heard about wireless pull cords? Do you know how they work?

These “pull cords”, which don’t actually have a cord, function via a sensor installed in the ceiling and an activation point on the floor. When you want to activate it, simply stand on this point, make a gesture with your hand as if you were pulling the cord of a traditional pull cord, and the door will open automatically. This solution guarantees hygiene as it doesn’t require you to touch any components and it’s also aesthetically pleasing as there’s no need for visible hanging cords.

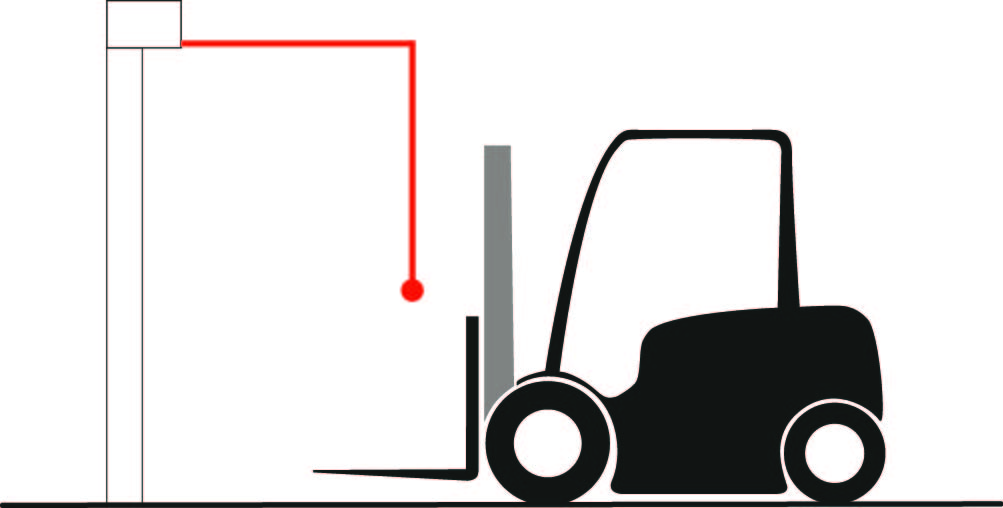

INDUCTION LOOP

A third option available is a magnetic field or induction loop. This alternative is the ideal solution if the facility is to be used almost exclusively for the passage of vehicles, such as pallet trucks.

This type of opening system is activated when the installed induction loop detects the presence of metal masses, like vehicles, meaning it’s also a hygienic solution.

How is it installed? Via a long, spiral cable that forms a closed circuit and is installed under the paving in a predetermined area close to the door, creating the magnetic field. Consequently, when it detects the presence of a machine/vehicle, there will be a change in the magnetic field, sending a signal that will activate the door and open it.

One common question about this system is regarding its sensitivity to a metal mass. The answer is simple as you can control its sensitivity from the control panel, adjusting it to suit your requirements and your facility.

OPENING SENSORS OR RADARS

Another opening system whose use is widespread is an opening sensor, which creates microwaves at an extremely high frequency and detects the passage of people and vehicles within its activation area, opening the door once their presence is noted.

It’s incredibly important that you consider the aim you hope to achieve through their installation. That’s because an opening sensor is easily activated as it doesn’t distinguish between people and vehicles, and its area of influence is very large, which could lead to situations in which the door is open for some time. Or it may be constantly opening and closing, leading to more energy consumption and wear and tear to the door.

However, there are opening sensors available that can distinguish between vehicles and people. These are more sophisticated but they allow the sensor to open the door only when people or vehicles access the area.

REMOTE CONTROL

One of the most traditional opening systems in recent years, which is used in industry as well as residential settings, is the remote control.

This opening system is used for automatic doors at industrial facilities as well as garage doors, although its control system is a little different in each case.

In terms of a remote control in an industrial facility, a receiver is installed inside the control panel, which allows any operator using a remote control to open the door via the receiver channel.

Can you have several channels or receivers with a single remote control? Yes, they can have several channels. The most commonly used has four channels, but there are also options with eight, 16 and 32 channels available.

What does this function offer me? Having several channels means that a single remote control can open different doors, with each channel corresponding to the receiver of a certain door. This means that a remote control with a single channel will only serve to open one door, but if a remote control has four channels, then it can open four different doors.

CONTACTLESS

One of the most innovative and most important options in recent months, given the epidemiological situation we’re experiencing with coronavirus (COVID-19), is contactless.

This opening system works in the same way as sensors, by creating microwaves that activate the door when they recognise movement in its area of influence. In addition, there are different options:

- Independent contactless point.

- Built into the door’s guide.

- Built into the control or button panel.

One of this option’s benefits is it’s completely hygienic, as there’s no need for any contact with the system. In addition, it’s efficient and effective, since it allows for faster movement between areas and it also enables greater energy savings to be made.

Which businesses or industries is it designed for?

Until recently, its use was widespread in the health, pharmaceutical and chemical industries that work with sterile environments, laboratories, and such like. However, there is a growing demand for it in all kinds of facilities, especially in those where there is contact with food, such as the agri-food industry.

RESTRICTED ACCESS (NUMERIC KEYPAD, CARD or KEY)

This kind of opening system aims to limit access to certain zones or areas inside a facility, ensuring that doors can only be used by authorised staff members, thereby guaranteeing secure access to the interior of a specific room or work area.

There are three different options within this category:

- Numeric keypad: This is a keypad containing numbers and symbols. It’s installed next to the door and a numerical code must be typed in to access the room.

- Access card: This panel has an opening and is installed next to the door. It needs a card to be inserted or swiped through the opening to access the room. Another type allows the door to open simply if the card is nearby or held on the panel.

- Key: The door control or button panel can also feature a lock. Only people who have the corresponding key may enter the work area inside.

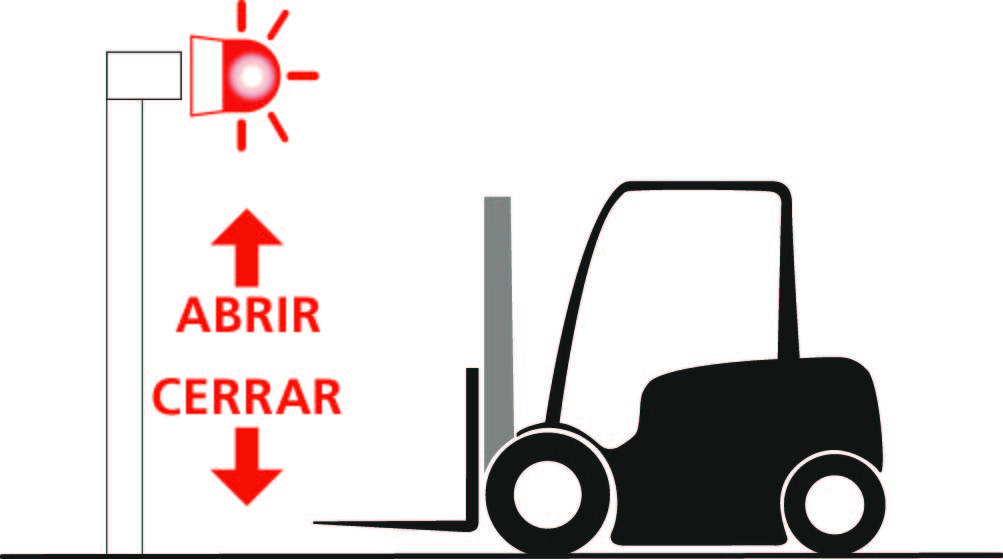

SAFETY LIGHT OR LIGHT WITH ALARM

Safety lights are an additional safety element that’s activated when the door is opened or closed. The most commonly used ones are safety lights and lights with alarms. In this case, the safety light is activated and it flashes and emits a warning sound while the door is moving so both vehicles and people exercise caution when trying to pass through the door or one of the areas where the door is installed.

This opening system is often used in places where the flow of people and vehicles is high and the aim is to ensure a safe, accident-free environment.

TRAFFIC LIGHT

The traffic light is a transit regulation component for vehicles and people, indicating when a door is open and you are able to pass through it (green) or when it’s closed (red) as the area on the other side may be occupied.

It’s used to ensure goods can circulate optimally inside the industrial premises.